Framing + Construction

Dead-Level Outdoor Constructions guarantees that all work complies with relevant building codes and standards. Additionally, care is taken to ensure that each construction is of the highest quality, aesthetically pleasing and will stand the test of time; outlasting similar constructions by other contractors.

It is common in the industry for builders to take short – cuts implementing only minimum required standards. Such practices often fail to meet the customer’s own expected standards. Poor quality can also result in the need for premature maintenance work, which in turn increases the overall cost in the long term. Whether or not you choose to have work done by Dead-Level Outdoor Constructions, you should ensure that your chosen contractor employs the methods mentioned below.

Framing Fixings

Many modern constructions are simply banged together using nail guns. Whilst this is a fast and efficient way to frame, over time and exposure to the elements, timber will naturally try to move. When nails are used the timber can pull apart at the joins. This weakens the structure and creates gaps where water sits. The structure will then rot prematurely, even where the best quality timber has been used.

Chris uses high quality alloy galvanized 14 gauge batten screws. These are durable in all outdoor applications including coastal areas. Due to the nature of the screw, the timber will not pull apart . If the head of the screw is stripped the screw cannot be pulled out without completely smashing up the piece of wood it has been driven into. In other applications quality galvanized brackets and bolts are utilized.

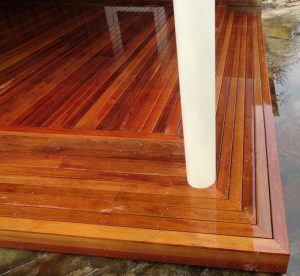

Deck Fixings

Special care is taken to enhance durability in areas within 5kms of the coast. Decking is fixed using 316 marine grade stainless steel decking nails with a deformed shank, so they do not pull out. In areas further from the coast quality galvanised nails are used, however customers can request the higher marine grade. When fixing wide decking boards, stainless steel or galvanised decking screws are used. Nails or screws are driven using a staggered pattern. This is important to prevent splitting of the timber joist.

Nails which are placed in a straight line combine to split the joist and open it up allowing both the nails to pull up and water to seep into the joist causing premature rot.

Balustrade Fixings

When installing balustrade cabling Dead-Level only uses 316 marine grade stainless steel cable and fittings. There is simply no substitute for marine grade stainless.

Further Measures to Ensure Longevity

Regardless of the quality and suitability of timber, all outdoor constructions will eventually succumb to rot. However measures can be taken to significantly enhance the structure’s longevity.

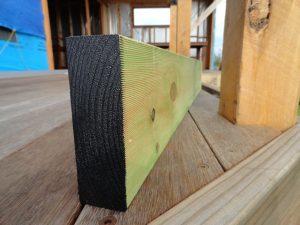

Timber rots in situations where it is not allowed to dry out properly and regularly. Most commonly rot occurs wherever timber is joined together, especially on the end grain of the wood. Water seeps into the joints of the timber frame and without air flow and sunlight it takes a lot longer to dry out. To prevent this all cuts and joins in timber frames are re-sealed with bitumen paint which provides a rubber membrane between each piece of timber. Coating the end grain in this way effectively more then doubles the lifespan of the construction. This practice is carried out on all Dead-Level frames regardless of the timber used.

On decks a rubber membrane is installed along the tops of all joists which provides protection to the frame from moisture gathering under the decking boards. The membrane is shaped to allow for rain to run off the decking and bypass the top of the joists where it would usually sit causing rot. As with using bitumen paint the installation of a rubber membrane will easily more than double the lifespan of your deck.